Current location:

Links:

-

Moreover, the design of panacea tomato cages caters to the ease and convenience of the gardener

panacea tomato cage. Often featuring circular or square shapes with multiple openings, they allow for easy access to the fruit and foliage. Pruning becomes a simpler task, and the fear of damaging the plant while harvesting the ripe tomatoes diminishes significantly. It's a thoughtful construction that aligns with the practical needs of both the plant and the gardener. When it comes to automotive components, coil springs play a crucial role in providing support and suspension to vehicles. These springs are designed to absorb shocks and vibrations from the road surface, ensuring a smooth and comfortable ride. Whether you're a car enthusiast or a professional mechanic, having the right coil springs can make all the difference in your vehicle's performance. In this article, we'll delve into the world of coil springs for sale and provide you with a comprehensive guide to help you find the perfect ones for your needs. Using 10mm angle beads in jewelry design can elevate a piece from ordinary to exceptional. When strung together, these beads form elegant lines and geometric shapes that catch the eye and invite closer inspection. They are particularly effective in bracelets and necklaces where their angles can be used to create symmetry or to disrupt it for a more dynamic look. Another common use for 1.2mm garden wire is for creating trellises or fences to separate different areas of the garden or to keep out unwanted animals. The thin but strong wire can be easily attached to wooden posts or stakes to create a barrier that is both functional and visually appealing. This can help to protect delicate plants from being trampled on or eaten by animals, as well as provide a sense of organization and structure to the garden. The 200mm wall tie is a standard size, chosen for its ability to provide adequate support over a wide range of construction scenarios. This particular size is typically selected for walls with a cavity width of 100mm, offering a balance between structural stability and minimal material usage. The 200mm length allows for sufficient penetration into both leafs of the wall, providing a robust connection that can withstand significant loads. Cattle Field Fence Ensuring the Safety and Security of Livestock Moreover, the weld mesh acts as a robust skeletal framework that enhances the bond between the concrete and the reinforcement

panacea tomato cage. Often featuring circular or square shapes with multiple openings, they allow for easy access to the fruit and foliage. Pruning becomes a simpler task, and the fear of damaging the plant while harvesting the ripe tomatoes diminishes significantly. It's a thoughtful construction that aligns with the practical needs of both the plant and the gardener. When it comes to automotive components, coil springs play a crucial role in providing support and suspension to vehicles. These springs are designed to absorb shocks and vibrations from the road surface, ensuring a smooth and comfortable ride. Whether you're a car enthusiast or a professional mechanic, having the right coil springs can make all the difference in your vehicle's performance. In this article, we'll delve into the world of coil springs for sale and provide you with a comprehensive guide to help you find the perfect ones for your needs. Using 10mm angle beads in jewelry design can elevate a piece from ordinary to exceptional. When strung together, these beads form elegant lines and geometric shapes that catch the eye and invite closer inspection. They are particularly effective in bracelets and necklaces where their angles can be used to create symmetry or to disrupt it for a more dynamic look. Another common use for 1.2mm garden wire is for creating trellises or fences to separate different areas of the garden or to keep out unwanted animals. The thin but strong wire can be easily attached to wooden posts or stakes to create a barrier that is both functional and visually appealing. This can help to protect delicate plants from being trampled on or eaten by animals, as well as provide a sense of organization and structure to the garden. The 200mm wall tie is a standard size, chosen for its ability to provide adequate support over a wide range of construction scenarios. This particular size is typically selected for walls with a cavity width of 100mm, offering a balance between structural stability and minimal material usage. The 200mm length allows for sufficient penetration into both leafs of the wall, providing a robust connection that can withstand significant loads. Cattle Field Fence Ensuring the Safety and Security of Livestock Moreover, the weld mesh acts as a robust skeletal framework that enhances the bond between the concrete and the reinforcement Water Treatment Industry The eco-conscious will appreciate their sustainability. Made from steel or other recyclable materials, they have a long lifespan and can be repurposed when needed. This quality aligns with the growing trend towards sustainable and reusable products.

Water Treatment Industry The eco-conscious will appreciate their sustainability. Made from steel or other recyclable materials, they have a long lifespan and can be repurposed when needed. This quality aligns with the growing trend towards sustainable and reusable products. Overall, metal wire grid panels are a versatile and practical solution for organizing and displaying items in a wide range of settings. Their durability, flexibility, and ease of use make them a popular choice for retailers, warehouses, garages, and homes looking to create efficient and visually appealing storage and display solutions.

However, it's essential to consider the impact on ride comfort

The primary advantage of metal wire mesh sheets lies in their inherent strength. The interlocking wires create a robust structure capable of withstanding significant mechanical stress, making them ideal for load-bearing applications such as flooring in industrial settings or reinforcement in concrete structures. Their resilience against corrosion and weathering, particularly in the case of galvanized or stainless steel variants, extends their lifespan and suitability for outdoor use. Another benefit of using a 19-inch tomato cage is its versatility. In addition to supporting tomato plants, these cages can also be used for a variety of other purposes in the garden

The primary advantage of metal wire mesh sheets lies in their inherent strength. The interlocking wires create a robust structure capable of withstanding significant mechanical stress, making them ideal for load-bearing applications such as flooring in industrial settings or reinforcement in concrete structures. Their resilience against corrosion and weathering, particularly in the case of galvanized or stainless steel variants, extends their lifespan and suitability for outdoor use. Another benefit of using a 19-inch tomato cage is its versatility. In addition to supporting tomato plants, these cages can also be used for a variety of other purposes in the garden

19 inch tomato cage. You can use them to support other vine crops such as cucumbers, peppers, or beans, helping to keep them off the ground and protected from pests and diseases. Wall reinforcement mesh, an integral component of modern construction techniques, plays a pivotal role in ensuring the structural integrity and durability of buildings. It is a grid-like structure made primarily from steel wires, designed to reinforce concrete walls, providing additional strength and stability. Another great use for black craft wire is in floral arrangements

black craft wire. You can use it to create stems for artificial flowers, or to add a decorative touch to a bouquet. Its flexibility makes it easy to manipulate into any shape you desire, making it the perfect material for creating unique and stunning floral designs. There are several reasons why using tomato cages is beneficial for your plants. First and foremost, tomato cages help to keep the plants upright and off the ground, which can prevent the fruit from rotting. In addition, cages provide support for the heavy vines and help to distribute the weight of the tomatoes evenly, reducing the risk of breakage.

Cavity wall ties

Furthermore, weld mesh reinforcement offers significant cost savings during construction. Its ease of installation and adaptability to various shapes and sizes means less time and labor are required for placement, speeding up the construction process and reducing overall project costs. In conclusion, the price of diamond wire mesh is a multifaceted calculation, involving a blend of material costs, manufacturing processes, market forces, and external economic factors. As a buyer, understanding these dynamics can help make informed decisions when sourcing this essential material. Remember, while cost is a significant factor, it's equally important to consider quality, durability, and the long-term benefits a product can offer. ```Annealed tie wire is specifically designed for tying applications. It is commonly used in construction to secure rebar and in agriculture for tying plants and vines. The annealing process gives this wire the necessary pliability to be easily twisted and tied without breaking, ensuring a strong and secure hold.

The 200mm wall tie is a standard size, chosen for its ability to provide adequate support over a wide range of construction scenarios. This particular size is typically selected for walls with a cavity width of 100mm, offering a balance between structural stability and minimal material usage. The 200mm length allows for sufficient penetration into both leafs of the wall, providing a robust connection that can withstand significant loads. Stainless steel wire cloth, also known as stainless steel mesh or woven wire mesh, is a highly versatile material that has found its way into numerous industrial, commercial, and even domestic applications due to its exceptional properties. This unique fabric is essentially a woven network of fine wires, primarily made from various grades of stainless steel, such as 304, 316, and 317, offering an ideal blend of strength, durability, and corrosion resistance. 4. Construction Springs are used in construction equipment, such as bulldozers and pile drivers, to absorb shock and protect sensitive components. The fixed knot fence, also known as the 'Hog Wire' or 'Field Fence', is a testament to the durability and resilience that comes with its design. It is constructed using vertical wires securely woven through horizontal wires at regular intervals, creating a strong and stable barrier. The fixed knot, where the horizontal wires are twisted around the vertical ones, provides the fence with its unique strength and flexibility, allowing it to withstand the test of time and the forces of nature. One way to save money on welded steel mesh is to purchase it in bulk One common type of timber frame tie is the Simpson Strong-Tie, which is made of galvanized steel and is designed to provide strong connections between timber frame components. These ties are often used in combination with bolts and screws to ensure that the timber frame structure is sturdy and secure. Chain link fences, known for their durability and versatility, are a popular choice for both residential and commercial properties. They offer a practical solution to security, privacy, and boundary demarcation needs. The height of a chain link fence is an essential factor to consider when selecting one, as it directly impacts its functionality and effectiveness. One of the primary advantages of steel-to-masonry ties is their adaptability. They can be customized to suit different types of masonry materials, such as brick, block, or stone, and can be installed at various stages of construction. Moreover, they offer excellent load-bearing capacity, making them ideal for high-rise buildings and structures in seismic zones. 2. Use annotations wisely Spring provides several annotations that simplify the implementation of hooks. For example, @BeanPostProcessor can be used to automatically register a custom bean post-processor, while @Component can be used to ensure that your hook is discovered and registered by the Spring container. In the heart of bustling markets and serene countryside lanes, one can often stumble upon a vibrant spectacle - tomato stands for sale. These humble stalls, piled high with plump, juicy tomatoes in shades of scarlet and vermilion, are more than just a marketplace attraction; they symbolize the essence of local agriculture, community, and the unbroken connection between the land and its people. Ladder Reinforcement for Brickwork A Robust Building Technique In addition to their durability, stainless compression springs are also highly resistant to corrosion. This is particularly important for applications in which the springs will be exposed to moisture or chemicals. By using stainless steel, manufacturers can ensure that their springs will maintain their strength and performance even in harsh environments. From that day on, the traveler never spoke of their experience in Bricktor's tunnels, for fear of what they had encountered in the darkness. And so the mystery of Bricktor, the town of bricks, remained intact, its secrets hidden away beneath the earth for eternity. Another significant advantage of bulk extension springs is their compact design

One common type of timber frame tie is the Simpson Strong-Tie, which is made of galvanized steel and is designed to provide strong connections between timber frame components. These ties are often used in combination with bolts and screws to ensure that the timber frame structure is sturdy and secure. Chain link fences, known for their durability and versatility, are a popular choice for both residential and commercial properties. They offer a practical solution to security, privacy, and boundary demarcation needs. The height of a chain link fence is an essential factor to consider when selecting one, as it directly impacts its functionality and effectiveness. One of the primary advantages of steel-to-masonry ties is their adaptability. They can be customized to suit different types of masonry materials, such as brick, block, or stone, and can be installed at various stages of construction. Moreover, they offer excellent load-bearing capacity, making them ideal for high-rise buildings and structures in seismic zones. 2. Use annotations wisely Spring provides several annotations that simplify the implementation of hooks. For example, @BeanPostProcessor can be used to automatically register a custom bean post-processor, while @Component can be used to ensure that your hook is discovered and registered by the Spring container. In the heart of bustling markets and serene countryside lanes, one can often stumble upon a vibrant spectacle - tomato stands for sale. These humble stalls, piled high with plump, juicy tomatoes in shades of scarlet and vermilion, are more than just a marketplace attraction; they symbolize the essence of local agriculture, community, and the unbroken connection between the land and its people. Ladder Reinforcement for Brickwork A Robust Building Technique In addition to their durability, stainless compression springs are also highly resistant to corrosion. This is particularly important for applications in which the springs will be exposed to moisture or chemicals. By using stainless steel, manufacturers can ensure that their springs will maintain their strength and performance even in harsh environments. From that day on, the traveler never spoke of their experience in Bricktor's tunnels, for fear of what they had encountered in the darkness. And so the mystery of Bricktor, the town of bricks, remained intact, its secrets hidden away beneath the earth for eternity. Another significant advantage of bulk extension springs is their compact design bulk extension springs. Traditional springs can take up a significant amount of space, which can be a problem in tight spaces or when size constraints are a concern. Bulk extension springs, on the other hand, are designed to be slender and lightweight, making them easy to integrate into a wide range of applications. Snake spacers are especially important in enclosures that have heating elements, such as heat lamps or heat pads. These devices can create hot spots in the enclosure, which can be dangerous for the snake if they are allowed to come into direct contact with the lid. Snake spacers help to prevent this by creating a barrier that keeps the snake from getting too close to the heat source. 4. Decorative Elements The unique geometry and mirror-like finish of rib lath stainless steel make it a popular choice for decorative elements such as handrails, screens, and furniture. The manufacturing process of small coil springs involves several intricate steps. First, the wire material is selected based on its strength, elasticity, and corrosion resistance. Then, it is coiled into the desired shape and size using specialized machinery. The coiling process must be carefully controlled to ensure that the spring has the correct number of coils and that they are evenly distributed The coiling process must be carefully controlled to ensure that the spring has the correct number of coils and that they are evenly distributed

bulk extension springs. Traditional springs can take up a significant amount of space, which can be a problem in tight spaces or when size constraints are a concern. Bulk extension springs, on the other hand, are designed to be slender and lightweight, making them easy to integrate into a wide range of applications. Snake spacers are especially important in enclosures that have heating elements, such as heat lamps or heat pads. These devices can create hot spots in the enclosure, which can be dangerous for the snake if they are allowed to come into direct contact with the lid. Snake spacers help to prevent this by creating a barrier that keeps the snake from getting too close to the heat source. 4. Decorative Elements The unique geometry and mirror-like finish of rib lath stainless steel make it a popular choice for decorative elements such as handrails, screens, and furniture. The manufacturing process of small coil springs involves several intricate steps. First, the wire material is selected based on its strength, elasticity, and corrosion resistance. Then, it is coiled into the desired shape and size using specialized machinery. The coiling process must be carefully controlled to ensure that the spring has the correct number of coils and that they are evenly distributed The coiling process must be carefully controlled to ensure that the spring has the correct number of coils and that they are evenly distributed The coiling process must be carefully controlled to ensure that the spring has the correct number of coils and that they are evenly distributed The coiling process must be carefully controlled to ensure that the spring has the correct number of coils and that they are evenly distributed

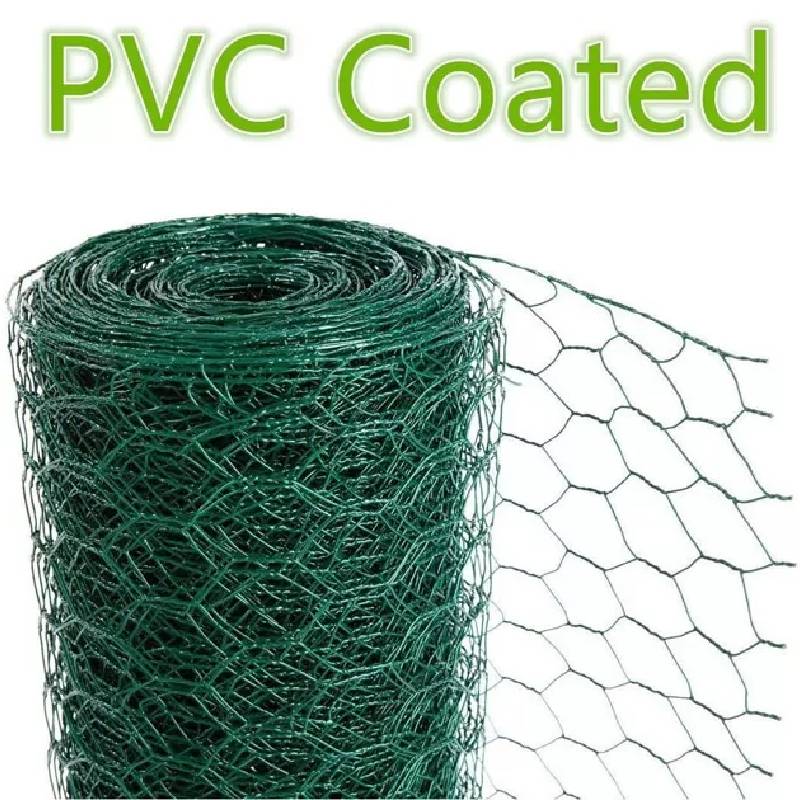

The coiling process must be carefully controlled to ensure that the spring has the correct number of coils and that they are evenly distributed The coiling process must be carefully controlled to ensure that the spring has the correct number of coils and that they are evenly distributed small coil springs. After coiling, the spring is heat-treated to relieve any internal stresses and to improve its overall durability. Finally, the spring is polished and coated to protect it from rust and wear. Another advantage of brick mesh walls is their thermal efficiency. The bricks act as a natural insulator, helping to regulate the temperature inside the building and reduce energy costs. This can be especially beneficial in colder climates where maintaining a consistent indoor temperature is essential. PVC coated galvanized wire is also highly flexible and easy to install

small coil springs. After coiling, the spring is heat-treated to relieve any internal stresses and to improve its overall durability. Finally, the spring is polished and coated to protect it from rust and wear. Another advantage of brick mesh walls is their thermal efficiency. The bricks act as a natural insulator, helping to regulate the temperature inside the building and reduce energy costs. This can be especially beneficial in colder climates where maintaining a consistent indoor temperature is essential. PVC coated galvanized wire is also highly flexible and easy to install server.compression.mime-types=video/mp4,application/octet-stream 3. ServletContextAware Similar to ApplicationContextAware, this hook allows a bean to receive a reference to the servlet context. This can be particularly useful for integrating with web-specific features, such as retrieving request parameters or setting session attributes.

server.compression.mime-types=video/mp4,application/octet-stream 3. ServletContextAware Similar to ApplicationContextAware, this hook allows a bean to receive a reference to the servlet context. This can be particularly useful for integrating with web-specific features, such as retrieving request parameters or setting session attributes. In modern construction, corrugated metal wall ties have evolved alongside advancements in engineering and technology. Today, they come in various sizes and types, catering to specific project requirements and architectural designs. From traditional applications in cavity walls to their usage in contemporary green buildings, corrugated metal wall ties continue to be a fundamental element in construction. Brick ties are usually made from materials such as galvanized steel, copper, or plastic, designed to withstand various weather conditions and resist corrosion. They are installed horizontally within the mortar joints of the brickwork, connecting each course of bricks to the stud wall behind. Their design varies, from simple wire ties to more complex anchor systems, but their function remains constant - to transfer loads from the brick skin to the wall cavity. The importance of masonry joint reinforcement is further emphasized in seismic regions. In earthquake-prone areas, it can significantly increase a structure's resilience by improving its ability to withstand lateral forces and prevent collapse. Regular inspections and maintenance of the reinforcement are crucial to ensure its continued effectiveness over time. In the heart of a bustling city, there stood an unusual sight - a tree with metal baskets instead of leaves. This wasn't your typical tree, but rather a work of art that had captured the imagination of many. It was a testament to human creativity and innovation, blending nature with technology in a way that was both beautiful and thought-provoking. In conclusion, the plasterboard external corner bead is an indispensable element in modern construction practices. It not only ensures the longevity and resilience of the plasterboard structure but also contributes to the aesthetics and overall quality of the finished project. As construction technology continues to evolve, so too will the design and functionality of these essential corner reinforcement tools, further solidifying their importance in the industry. In conclusion, welded wire mesh for sale presents a multitude of possibilities for various industries. Its durability, versatility, and ease of use make it an indispensable material. Whether you're looking to reinforce structures, secure perimeters, or create functional enclosures, choosing the right welded wire mesh can significantly enhance the efficiency and longevity of your project. So, delve into the world of welded wire mesh, and discover how this seemingly simple product can bring a touch of innovation and resilience to your next venture. Despite their small size, wire clips contribute greatly to the overall sustainability of a building. By reinforcing the connection between the masonry and the structure, they ensure a longer lifespan for the wall, reducing the need for frequent repairs or replacements. This, in turn, lessens the environmental impact associated with construction waste.